Let’s talk about pancakes. The perfect batch of pancakes is really only as good as the batter dispenser mechanism used to drop the right amount of batter into the pan. Too much batter and your pancakes could be too dense; too little batter and your pancakes will have too little structure or shape. In either situation, the proper amount of this foundational ingredient is perhaps the most important element to ensure you have a high quality end product.

Now, let’s take our pancake example and relate it to concrete batching plants and the need for properly dosing the right amount of admixture to ensure a durable and high-end final product. Regardless of whether you’re using chemical or mineral admixtures, concrete batching plants need accurate, reliable dispenser systems to effectively and efficiently incorporate these additives with versatility and flexibility for use in a variety of applications.

But with so many dispenser systems available for concrete batching plants, the question becomes: What are the most critical elements to consider when selecting the right dispenser system for your concrete batching plant? Let’s look at the types of dispenser systems, their functionality, and the factors to consider when choosing the right dispenser system for your needs.

What are the common types of dispenser systems?

Before we take a look at some of the prime factors to consider in selecting a dispenser system, let’s take a quick, high-level view of the more common types of dispenser systems for a better understanding of how they can best be deployed and the value propositions they provide for concrete batching.

- Metering pump dispensers: Used for volumetric batching, metering pump dispensers are ideal for Volumetric Mixer Plants where small amounts of admixture need to be integrated on a continuous, controlled basis. Whereas in a batch mixer all ingredients are charged into the mixer in a predefined sequence, volumetric concrete batching requires constant, consistent entry and exit of liquid with a high-degree of accuracy and efficiency.

- Direct feed dispensers: Designed and engineered for high doses of admixture in larger concrete batching operations, direct feed dispensers are ideal for additives like accelerators, corrosion inhibitors, and plasticizers, as well as the addition of job site admixtures. Direct feed dispensers provide accurate, reliable dosing directly into the concrete, and the option of manual, semi-automatic, or computer interface provides versatility and flexibility for the operator in control and insight into the mixing process.

- Bottle or measuring unit dispensers: Also engineered for manual, semi-automatic, and interface control and operation, bottle dispensers are best when visual verification of admixture addition is required for effective and efficient batching processes. This system is designed for such admixtures as air entraining, water reducer, or retarder admixtures to help reduce the segregation of admixture, slow settling time, and enhance the overall workability of the concrete.

- Truck-mounted concrete dispenser: Operating on a just-in-time principle, truck-mounted concrete dispensers are best suited for admixture dispensing where concrete is required on an intermittent basis. Admixture dosage is conducted upon arrival at the job site. Mixing and blending of concrete takes place on a continuous basis and the operator can stop the mixing and delivery process and restart it at any time depending on the job or requirements of the application.

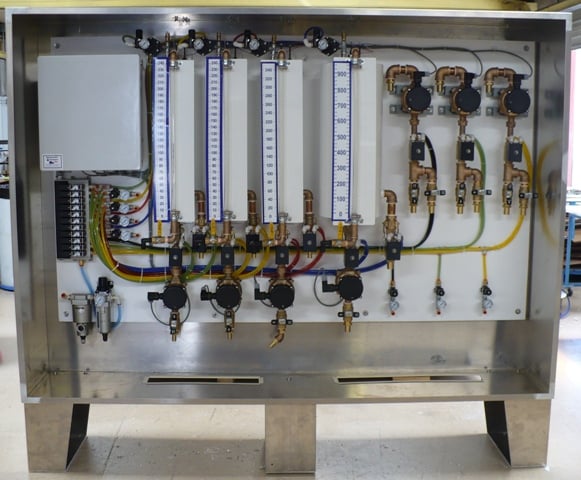

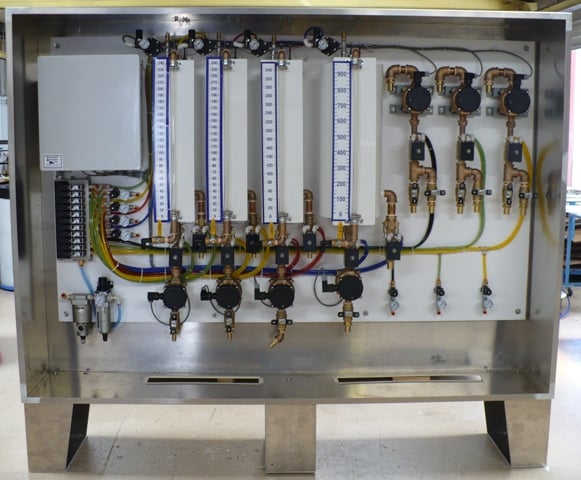

.jpg?width=4608&name=IMG_0008(1).jpg)

What are the factors to consider in choosing a dispenser system?

Now we can look at the contextual or application-based factors to weigh when choosing the right dispenser system for your concrete batching needs. It’s important to note that local and state Department of Transportation offices have varying regulations on where certain dispenser systems can be used — and of course, these mandates can vary widely on a state-by-state basis. Whereas some DOTs will allow use of a direct feed dispenser with a plasticizer admixture, others DOTs will require a bottle dispenser system instead.

In addition, most DOTs will not allow concrete use on state or federal jobs unless it is batched through an automated system, which would deem manual or semi-automatic dispensing systems unacceptable.

Other factors to consider when choosing a dispenser system include:

- Type of concrete batching plant: The right concrete dispenser system depends greatly on the type of concrete plant. Whether it’s a precast, ready mix, or volumetric plant, each concrete batching facility has its own set of processes and criteria that make it well-suited for a certain type of admixture dispenser. For example, an operator at a volumetric mixer plant would be well-served choosing a metering pump dispenser as opposed to a direct feed or bottle dispenser given the relatively small volumes of concrete being produced. On the flip side, a direct feed dispenser system is ideal for a ready-mix concrete plant for large jobs where mixing space is at a premium and the final product needs to arrive on-site ready for use.

- Type and dosage of admixture: It’s important to weigh the kinds of admixtures and the dosage rate and amounts used when determining which dispenser system will yield the greatest productivity and precision. For example, both the type and dosage rate of admixture required for concrete play a key role in the size of the pumps, valves, and meters on direct feed dispensers, and the same goes for the bottle size, pumps, and values with bottle type dispensers.

- Type of batch control panel: What kind of insight and visibility does your plant have into the batching process? How many admixture dispensers can be controlled by a batch panel? What voltage does a given batch panel provide for admixture fill and discharge signals? These are just a handful of questions plant operators need to address in determining the right dispenser for their application. As with nearly every other corner of the manufacturing, production, or fabrication space, the ability to control and achieve visibility and transparency across every production process is vital for optimizing productivity and quality, and considering how a dispenser system can integrate into your batch control panel is no different.

As you can see, the factors in choosing the right dispenser system for your concrete batching plant are varied and somewhat complex. However, Industrial Pump and Equipment can help you discover the right dispenser system to suit your concrete batching needs. Since 1967, IPEC has been a trusted supplier of admixture dispenser systems and has helped concrete plants achieve best-in-industry efficiency.

Learn more about how IPEC’s line of Badger Meter and Dispenser Systems, Inc. pumps and dispenser systems can help you stay one step ahead of the competition and unlock enhanced productivity and growth.