There’s often much confusion in today’s general manufacturing space about the true nature of positive displacement pumps. In fact, PD pumps are frequently lumped together with centrifugal pumps, which further muddies the waters in terms of how PD pumps work, their real-world value proposition, and which industries or applications are the best fit to maximize performance.

The good news for you is that the confusion, conflation, and chaos around positive displacement pumps ends here. Today. With this very blog entry. We’ll start with a simple, workable definition. PD pumps trap fixed amounts of fluid within the system to create a constant, consistent flowrate that is independent of pressure. Additionally, because of this consistent nature of fluid movement, PD pumps are a mission-critical tool for environments where high-degrees of dosing accuracy is key.

But to better understand what we talk about when we talk about positive displacement pumps, let’s examine three common questions about this kind of pumping system to help you understand if a PD pump is the right fit for your application.

What are the main categories of positive displacement pumps?

PD pumps can be broken into two distinct types or classifications each with unique characteristics, operating elements, and best applications. While understanding the fundamental differences between each type of PD pump is of course important, it’s just as important to remember that each of these PD pump types exists under an umbrella of precision, high volume and pressure, and consistency in flowrates. Keeping this at top of mind will help avoid the pitfall of confusing PD pumps with other kinds of pump solutions.

- Rotary pumps: Rotary positive displacement pumps use rotating cogs or gears to transfer or move fluids throughout the system. The rotating component creates a liquid seal with the pump casing and creates suction at the inlet. Fluid is then drawn into the pump, enclosed within the teeth of its rotating cogs or gears, and transferred to the discharge. The most common types of rotary PD pumps are gear pumps (which use either an internal or external gear mechanism to draw and discharge fluid); rotary vane pumps that use vanes mounted within the pump to move fluid; and progressive cavity pumps that push fluid via fixed shape cavities inside the pump system.

- Reciprocating pumps: A reciprocating PD pump works by the repeated back-and-forth movement of one of three major mechanisms or systems: piston or diaphragm; pneumatic; or hose diaphragm. In a piston pump, the piston creates a vacuum, opens an inlet valve, closes the outlet valve, and draws fluid into the piston chamber. As the motion of the piston reverses, the inlet valve closes and the outlet valve allows the fluid to be discharged through the system. With a pneumatic PD pump, pressurized gas or air moves and directs fluid through the pump apparatus. Finally, a diaphragm pump deploys flexible membrane moves fluid by expanding and compressing the diaphragm.

Can positive displacement pumps be used in more than one application?

The short answer is yes — however, as with every tool, there is a defined sweet spot to help maximize the effectiveness of PD pumps. We’ve outlined that PD pumps are ideal for applications where high-levels of accurate dosing and high pressure output is required, and while these parameters can apply to a wide variety of industrial contexts, industries such as oil & gas, chemical, concrete, and water treatment are where PD pumps distinguish themselves as a mission-critical ingredient for optimizing an industrial fluid system.

What also equips PD pumps for optimal performance in the oil & gas, chemical, and concrete space is flowrates are only dependent on the speed of the main piston, shaft, or other driving mechanisms.

Once again, the comparison to centrifugal pumps here is inevitable, but unlike centrifugal pumps, PD pump production and efficiency is not impacted by pressure variables. This makes PD pumps a superior choice where fluid supply is irregular or inconsistent.

Are positive displacement pumps as efficient as centrifugal pumps?

To understand the efficiency of PD pumps is to understand the Best Efficiency Point (BEP) curve. Simply put, BEP is the point along a pump curve where efficiency is the highest. Pumps should be selected to operate as close to BEP as possible.

Pumps operating at BEP use input power as efficiently as possible, which reduces energy consumption and costs and helps prolong the service life of the pump. Pumps functioning at BEP also produce low vibration readings to help keep maintenance costs in check and reduce the likelihood of downtime or gaps in optimized production.

While centrifugal pumps have a defined ceiling relative to BEP, PD pumps can provide optimized pump efficiency at any point on the BEP curve. Combined with the capability to provide consistent fluid flow at constant RPM regardless of pressure fluctuations, PD pumps offer enhanced flexibility and maneuverability as a versatile workhorse in applications where precise dosing and metering functionality is required.

Why work with IPEC on your positive displacement pump solution?

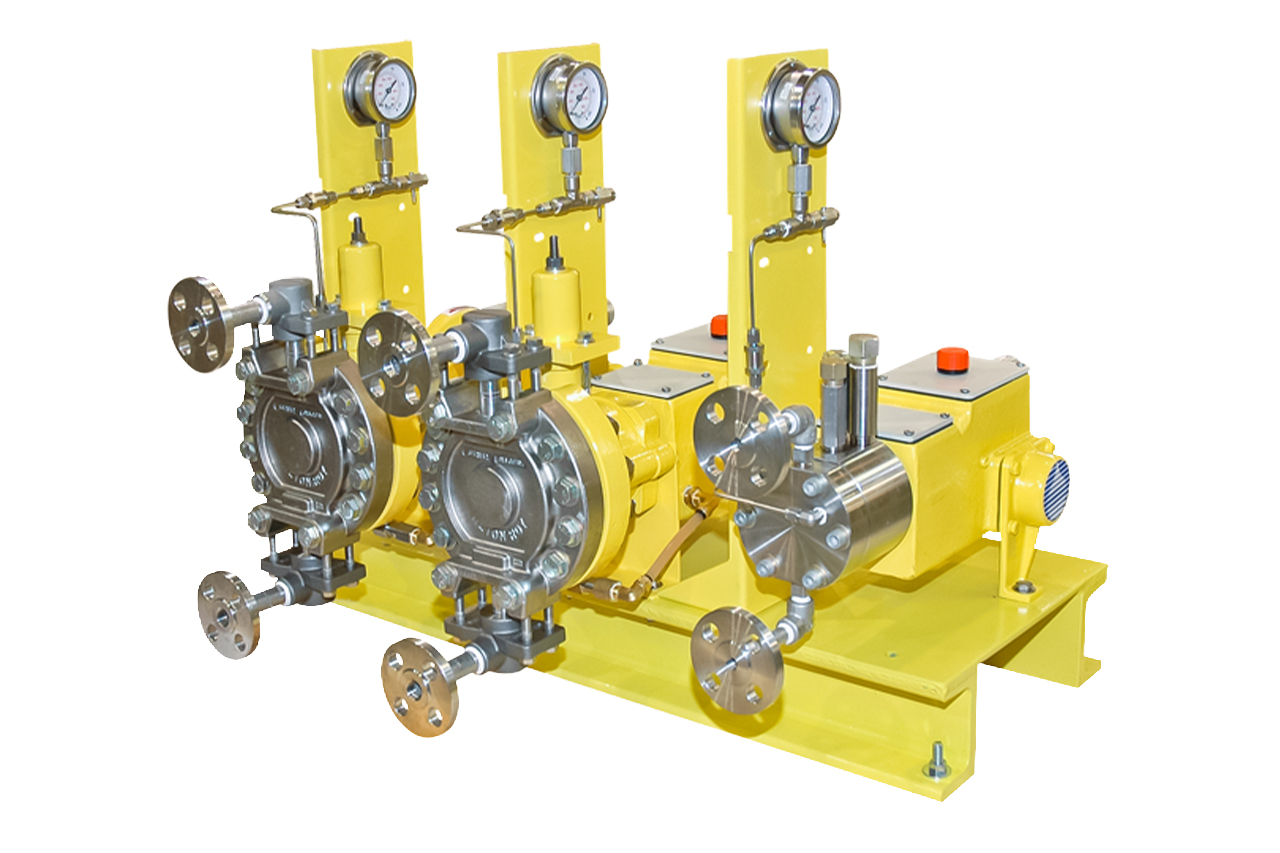

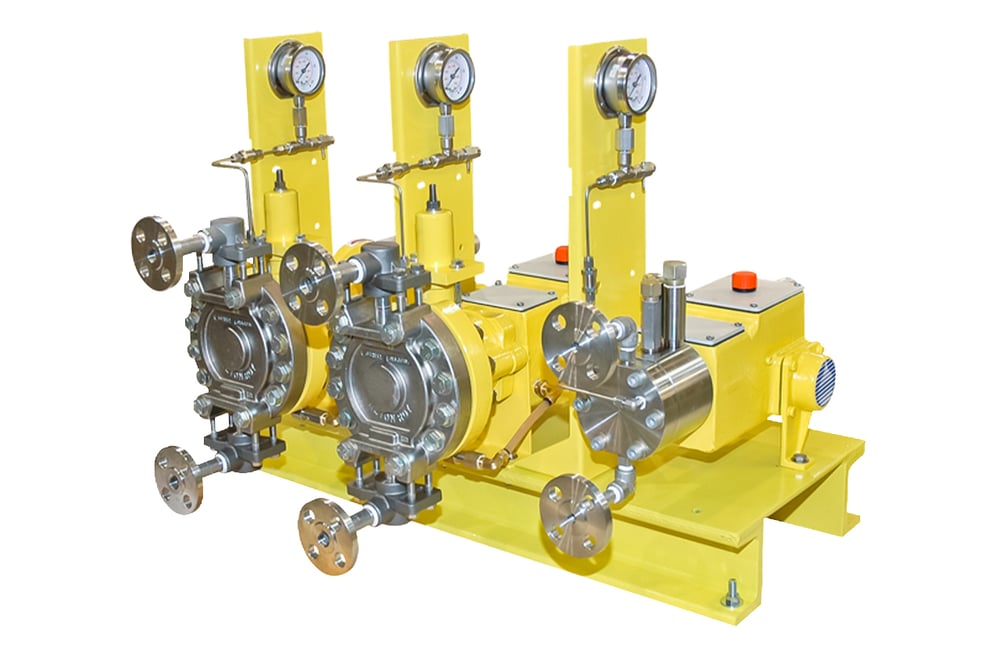

IPEC has more than 50 years of industrial pump solution knowledge, expertise, and service. Our pump technicians provide custom PD pump solutions for applications like chemical feed, polymer feed, high pressure methanol injection, surface water treatment, and more. Our partnership with industry standard brands such as Milton Roy, LMI, Yamada, and Albin allows us to offer the most innovative, state-of-the-art PD pumps on the market today to help you achieve superior process optimization and productivity.

Coupled with pump solutions of unparalleled quality, IPEC’s experience in the oil & gas, chemical/petrochemical, concrete, and general industry space offers the expertise, insight, and service to help you discover how the right PD pump can positively enhance your processes and help you do what you do faster and more accurately.

Learn how positive displacement pumps from IPEC can help you rethink your industrial pump solution.