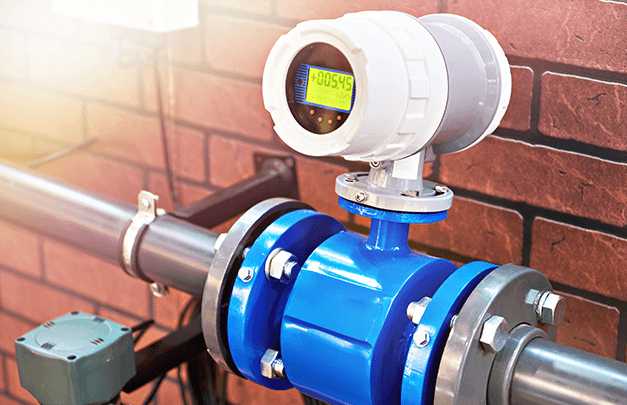

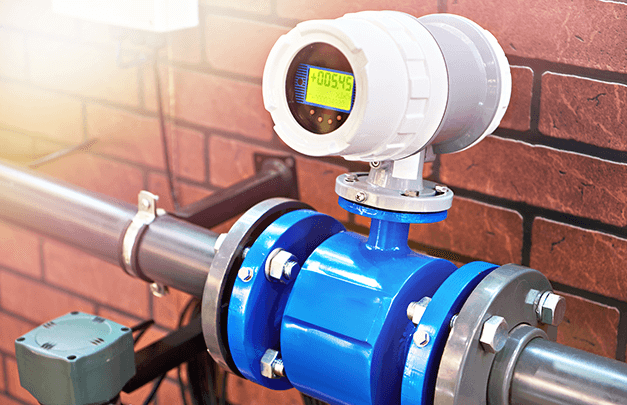

There is a fine balance to the timing of when plant operators recalibrate their industrial flow meters. Failure to recalibrate your flow meter can hamper performance, diminish your productivity, and reduce your process efficiency. Recalibrating an industrial flow meter too soon can fail to produce desired productivity and efficiency results, and this can result in wasted time, resources, and costs.

While establishing a plant-wide recalibration plan can help, the unique deployments and applications of today’s industrial flow meters call for more custom recalibration cycles that are based largely on the performance of individual meters. This can create a level of uncertainty and complexity when it comes to optimizing your industrial flow meter performance.

Here, we’ll look at five questions to ask to better determine whether your industrial flow meter needs recalibration, and what you need to know to facilitate a successful recalibration process.

1. When was your last plant-wide instrument assessment?

A plant-wide assessment of industrial instrumentation includes a holistic evaluation of industrial flow meters. This instrument assessment helps review and document a wide range of operational, application, and performance information, including the location and condition of your flow meter; operating and/or environmental conditions; performance data; and the date of deployment.

Once this information is gathered and documented, a plant-wide instrument assessment also includes determining whether industrial equipment requires maintenance and troubleshooting, and whether each individual piece of equipment is leaving the door open for potential safety issues. This kind of plant-wide assessment can provide a great deal of clarity in deciding whether it’s time to recalibrate your flow meters.

2. Have you prioritized — or categorized — your flow meters?

After flow meters have been installed and brought online, it’s important for plant operators to categorize each meter based on four different levels of critical importance. These levels assign a level of importance or priority to each flow meter relative to the productivity of plant operations. The four categories include:

- Critical for the product, which are flow meters that have a direct impact on the quality of the final product.

- Critical for the process or system, which include flow meters that have a direct impact on processes or workflows, but that do not diminish the quality of the end product.

- Critical for safety, which are flow meters that directly impact the safety and well-being of the plant environment and the technicians on the production floor.

- Non-critical, which are flow meters that do not directly impact any of the above

Adequately categorizing industrial flow meters can help you assign priority to when certain meters need to be recalibrated compared to other industrial meters or equipment.

3. Have you reviewed recent flow meter diagnostic data from your asset management system

The importance of an asset management system cannot be understated, especially as 24/7 production cycles become commonplace and plants deploy a larger number of industrial flow meters in order to keep pace with demand. Not only does an asset management system help you document and track performance data and operational state of equipment like flow meters, it also helps provide key diagnostic data.

These can be important signs that your flow meter needs to be recalibrated, or that your meter needs some level of troubleshooting to restore peak performance.

4. How frequently are your industrial flow meters recalibrated

Similar to how it takes a little time to break in a new pair of loafers to ensure a proper and comfortable fit, newly installed flow meters may need to be recalibrated more frequently as they integrate into an existing plant infrastructure. On the other hand, industrial flow meters with a longer deployment history can require less frequent recalibration and maintenance.

As a result, the date when your flow meter was installed and how recently — and frequently — can help you determine whether recalibration will address any efficiency or productivity issues.

5. Where was your flow meter last recalibrated?

The location where your flow meter was last calibrated can play a large part in the performance of your meter and whether recalibration is necessary. The two most common environments for flow meter recalibration are on-site vs lab, and each provide unique challenges and opportunities for flow meter calibration.

Lab calibration requires sending the flow meter to a designated, more controlled facility. This can produce more accurate, lasting calibration, but it can also be more costly and result in longer periods of downtime. On-site calibration can be completed anywhere using portable calibration equipment, and, while this helps minimize downtime and freight costs, it can result in less accurate or lasting calibration.

IPEC’s expert industrial flow meter technicians have the tools, resources, and experience to help you determine whether recalibrating your flow meter is necessary, and how recalibration can increase the efficiency of your meter.

Plus, our teams can execute on-site or lab calibration processes, and our expanded warehouse and inventory of component parts can help troubleshoot your flow meter to optimize productivity.

Contact us to learn more about how we can help with your industrial flow meter needs.