When batching additives or water into your concrete mix, it’s vital that each component is added to the mix accurately. When concrete and admixtures are not properly mixed — or if water is not added in the right proportion — workability is not guaranteed. Your meter and transmitter can help you batch accurately every time, but how do you calibrate it? Here, we’ll discuss how to calibrate your meter for accurate batching.

Why calibrate?

When your plant needs to pump cold water — or hot water in the winter — the amount must batch consistently. If the meter’s rotating element has worn over time or if slippage occurs within the pump, your water meter may need to be recalibrated.

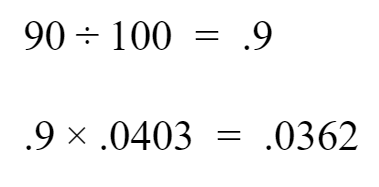

For example, consider a mix that requires batching 100 gallons of water after adding aggregate and chemicals. Over time, the operator notices 90 gallons are being added instead of 100. At this point, the amount of water must be adjusted, and this can be done by changing the scale factor programmed into the Badger electronic scaler board. To change the scale factor for accurate batching, use this easy formula: Quantity delivered ÷ quantity pre-set × the scale factor currently set on the transmitter board to adjust for the 10 gallon difference.

Calibrating your water meter

When calibrating your water meter, begin by running a test batch. Enter the pre-set amount — in this case, 100 gallons — into your batch controller or batch panel. If you select 100 gallons and see 90 gallons instead, use the formula above to divide 90 (the quantity delivered) by 100 (the quantity pre-set) and then multiply it by the scale factor currently programmed into the transmitter scaler board.

Using 0.0403 as an example of a scale factor, we can plug in the entire formula. 90 ÷ 100 = .9. .9 X 0.0403 = .0362. .0362 will be your new scale factor.

Once you have entered the new scale factor into the scaler board then run another batch of 100 gallons to verify accuracy.

Properties of hardened concrete

The properties of concrete change based on the batching and mixing process. Examples of these aspects include:

Strength, which will vary based on the stability of the cement and quantity of water added into the mix. Adding too much to the mixture will lower its strength, as will non-uniformity and inaccurate mixing.

Durability. If water or aggregates aren’t proportioned into the mix properly, it will negatively affect durability. Batching water and aggregates accurately will ensure that concrete will remain consistent from batch to batch and that it will maintain strong over time.

Surface finish and texture. Depending on what’s added into a mixture, the appearance and texture of concrete can change dramatically. Whether you need a certain color or level of smoothness, the end result will depend on the mixture and is dependent upon batch accuracy. If a mix is inadequate, it will lead to poor surface finish and texture, which will also impact durability.

Accurate batching is essential for a high-quality and durable concrete mixture. To keep your batches consistent, recalibrate your water meter every now and then for a strong and long-lasting result. Looking for a meter that will help you produce accurate batches every time? Visit our online store to browse options.