The use of high-viscosity fluids is common in a wide range of manufacturing environments, everything from food & beverage production to the drilling and refining of oil & natural gas. Regardless of the application, high-viscosity fluids can be challenging to handle and can require specific industrial pumps and flow meters to optimize both efficiency and productivity.

The use of high-viscosity fluids is common in a wide range of manufacturing environments, everything from food & beverage production to the drilling and refining of oil & natural gas. Regardless of the application, high-viscosity fluids can be challenging to handle and can require specific industrial pumps and flow meters to optimize both efficiency and productivity.

The reason?

Unlike low-viscosity fluids such as water, high-viscosity fluids are more resistant to consistent flow rates, and environmental factors like temperature fluctuations can increase a fluid’s viscosity and make maintaining consistent flow rates even more difficult. When you take into account that so much of modern manufacturing happens in uncontrolled environments, maintaining consistent flow rates with high-viscosity fluids becomes a top concern.

Here, we’ll look at what plant operators should know about working with high-viscosity fluids, and how to choose the right industrial pump to facilitate an efficient, cost-effective use of these fluids.

What are some common issues with pumping high-viscosity fluids?

The challenges that come with pumping high-viscosity fluids center largely on operational efficiency and the long-term reliability and durability of your pump system — and these two factors can greatly impact your ability to not only provide a quality product, but also grow your business and increase market share.

Some of the more common issues with pumping high-viscosity fluids include:

- Reduced or inconsistent flow rates, in large part because more viscous fluids move at a slower rate

- Increased risk of cavitation, which occurs when vapor bubbles form in the liquid. This condition can cause undue wear and tear or or even significant damage to the pump

- Increased energy consumption and costs, because processing and handling more viscous fluids can require more power. This can also increase your carbon emissions and result in a greater waste of resources

- A shorter pump service life, as pumps that process high-viscosity fluids may require more frequent maintenance intervals. If these intervals are not consistently adhered to, pumps have a greater likelihood of breakdown or failure, causing unplanned downtime and increased repair or replacement costs

What are the key considerations in choosing the right pump for use in processing high-viscosity fluids?

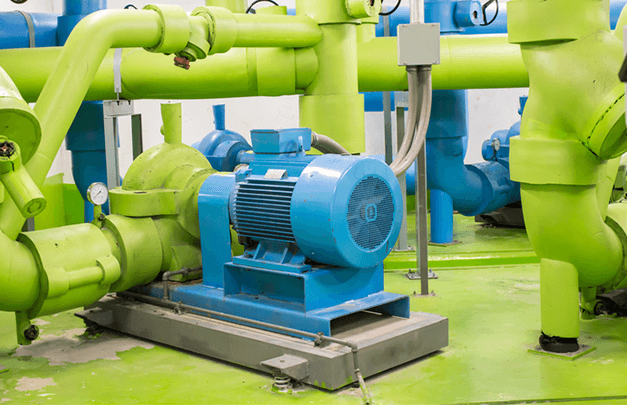

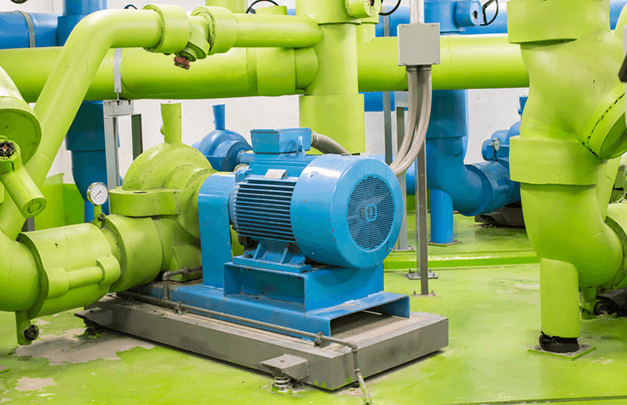

The ability to consistently process high-viscosity fluids in a variety of strenuous or uncontrolled applications makes positive displacement (PD) pumps the ideal choice for both performance and efficiency.

PD pumps can deliver high-viscosity fluids with a higher level of pressure, and PD pumps can also help plant operators enhance fluid transfer efficiency at any point on the Best Efficiency Point (BEP) curve, which is a mission-critical characteristic in optimizing your use of resources and creating consistent dosing and metering.

Some key considerations when choosing the right PD pump for processing high-viscosity fluids include:

- The ability to produce consistent, reliable flow rates with high degrees of accuracy

- The capacity to execute high-differential fluid pressures

- Minimal risk of cavitation

- More efficient engineering that can reduce energy consumption without sacrificing power and performance

For example, Milton Roy manufactures positive displacement pumps that are designed to provide high flow rates with more viscous fluids at a consistent temperature to ensure fluids do not increase in viscosity during operation. Milton Roy’s PD pumps can produce flow rates of up to 2245 GPH, even with variations in discharge pressure. Compliance with API 675 standards makes Milton Roy’s PD pumps ideal for use in a variety of demanding applications, including the oil & gas industry.

Why partner with IPEC on a pump solution for high-viscosity fluids?

With more than 70 years of industrial pump experience and knowledge, IPEC has what it takes to help you find the ideal high-viscosity pump or flow meter solution for any application. Aside from our longstanding partnership with Milton Roy, we also offer a range of Yamada pumps, many of which are compliant with Food and Drug Administration (FDA) guidelines for use in food & beverage processing facilities.

IPEC’s expert team of engineers can help you design custom solutions to help you overcome industry or application-specific challenges. Plus, our maintenance teams have the skills and expertise to conduct on-site equipment audits and performance enhancements to help optimize your equipment for 24/7 production, and our warehouse offers a large inventory of products and components parts to help you maximize productivity and reduce unplanned downtime.

Contact us to learn more about the right industrial pump for your high-viscosity application, or you can also browse our online store.